HempWood® Organic Flooring

Transform your home or business with HempWood Organic Flooring!

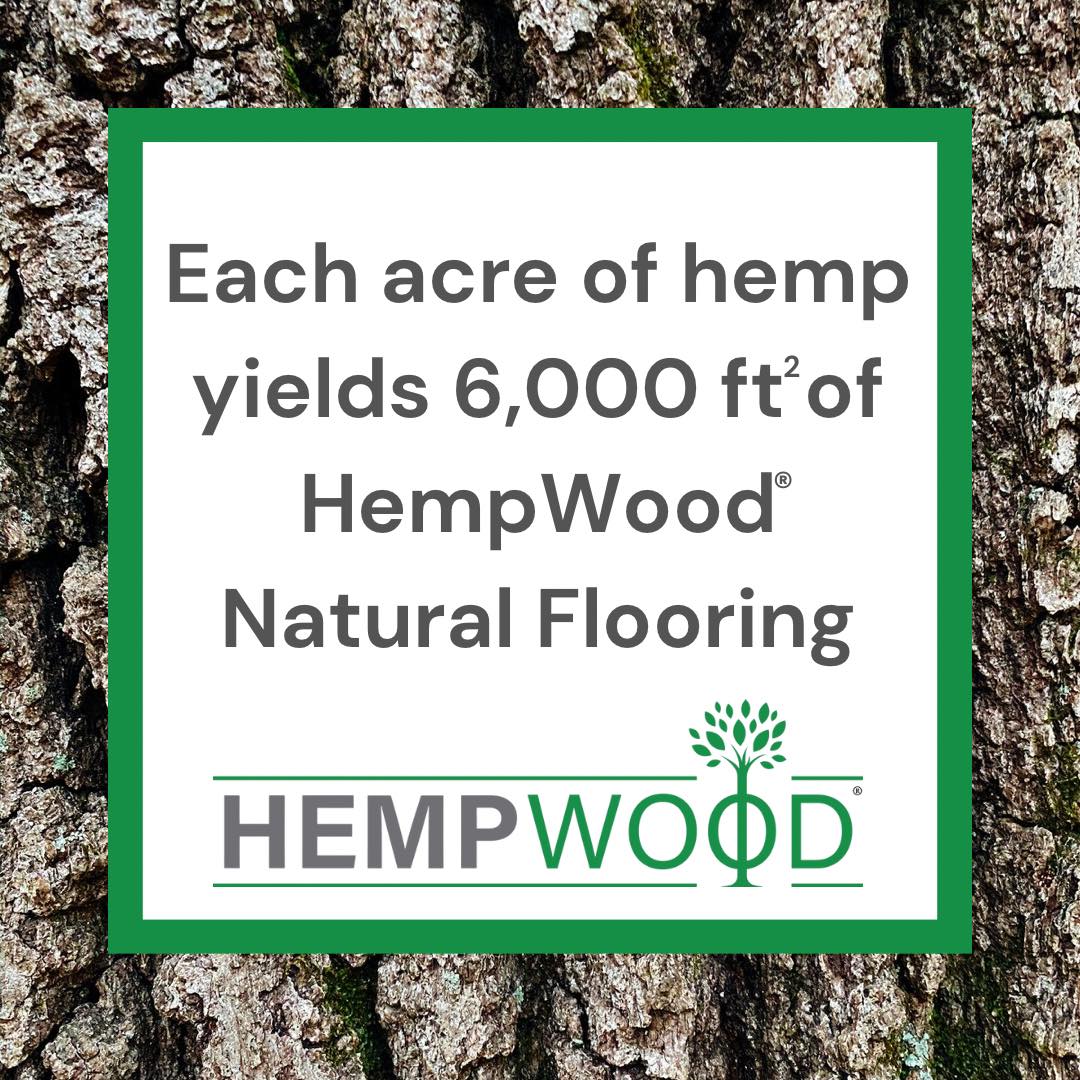

This American-made floor covering goes from seed to floor within 150 days – that’s faster than bamboo! And, with a Janka hardness rating of 2,200 lbf, this engineered hardwood is ready to withstand what life has to offer. Yes, including pet nails. Not to mention, HempWood Natural Flooring is a USDA Certified BioBased product and is carbon-negative from cradle to gate.

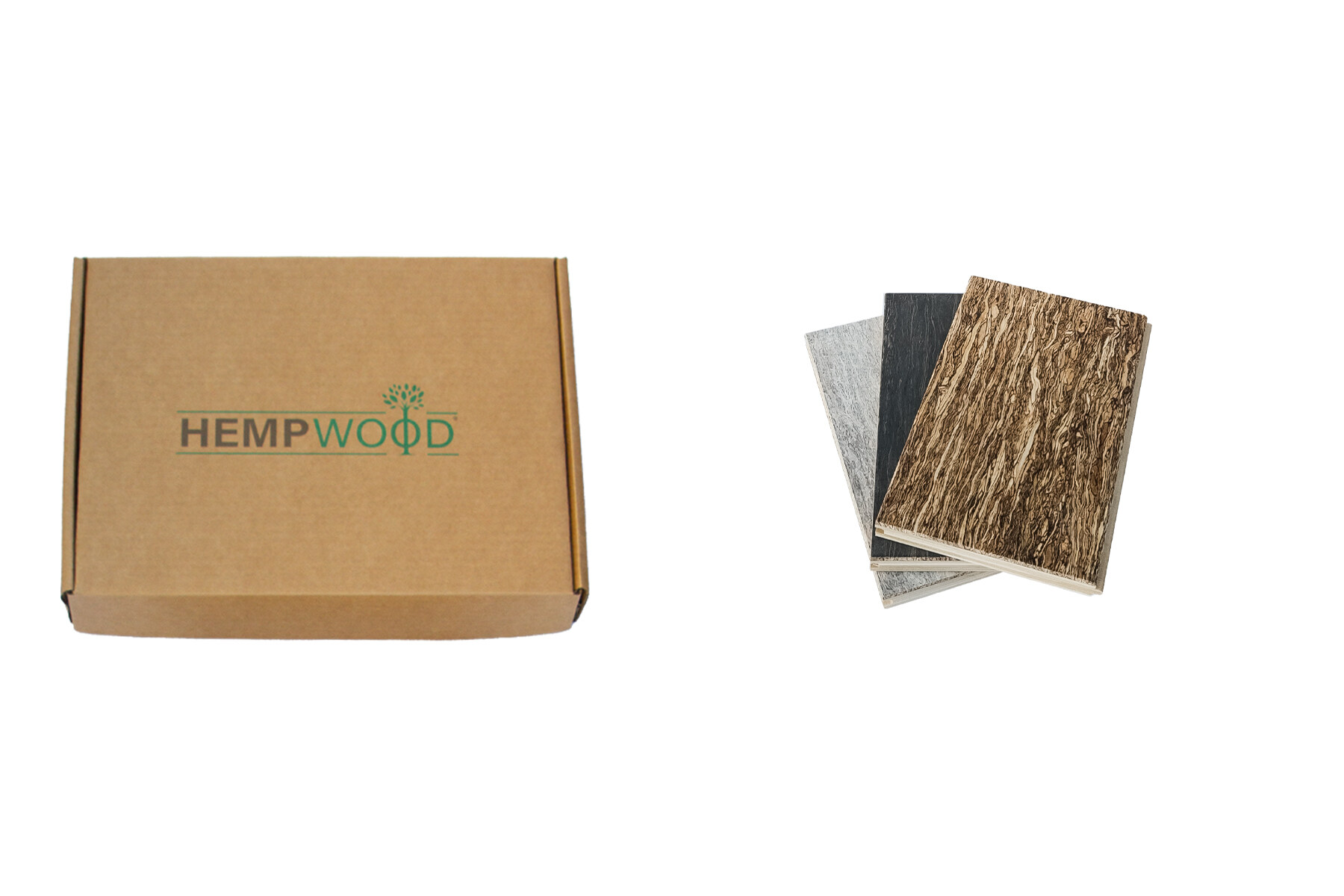

Get your samples today.

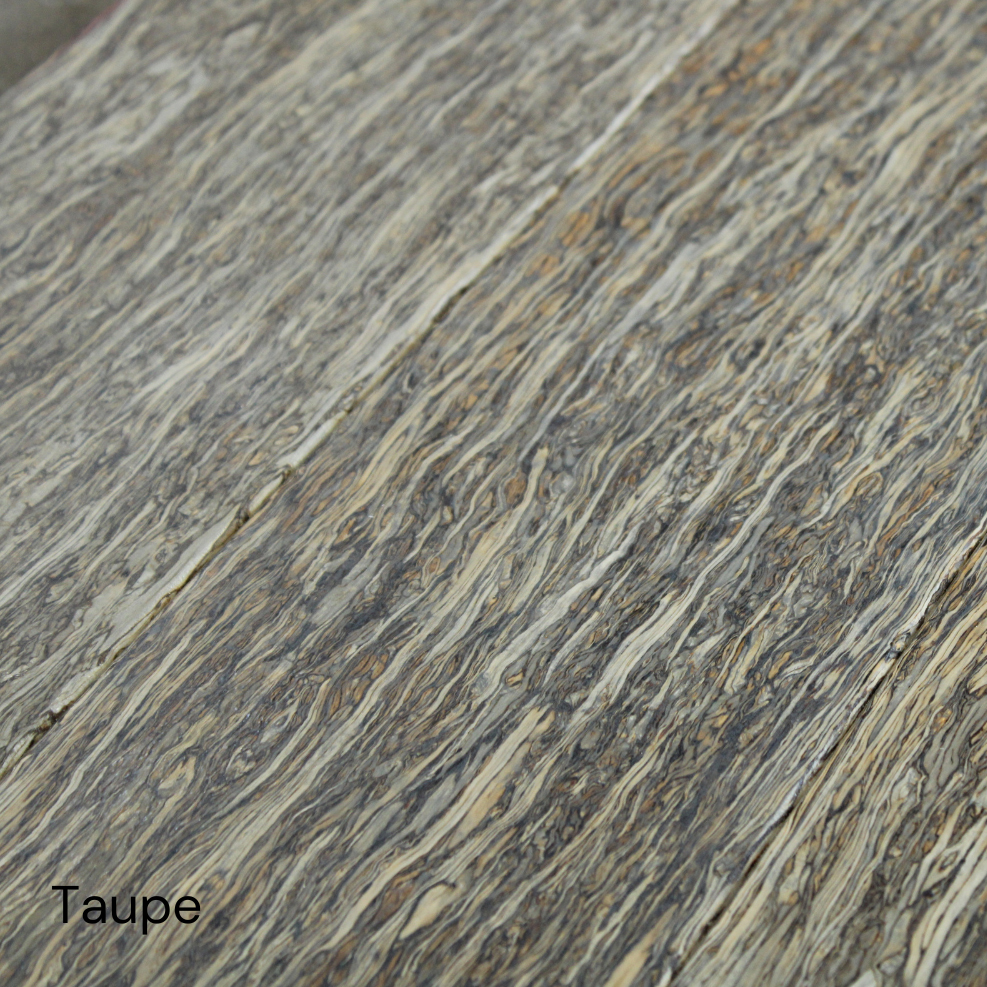

Flooring Color Options

How is HempWood® Organic Flooring Made?

The process of creating HempWood® Organic Flooring starts in the field. All hemp is sourced within 100 miles of the factory from local farmers. After the hemp is collected, a plant-based adhesive is used to bind full-length fiber hemp stalks. After the hemp stalks and plant-based adhesive are combined, the material is compressed and baked to form HempWood® Blocks.

From the Blocks, 4mm HempWood® veneers are cut for the top layer of the engineered flooring.

For the substrate, a 5-layer PureBond® Hardwood Plywood is used. The plywood is ethically sourced from Columbia Forest Products, which is located in West Virginia. By using PureBond® Plywood, we are able to maintain our eco-friendly mission and support the American economy.

After cutting the veneers and ripping the plywood, our flooring is assembled with the help of our PUR glue line. After adhering the HempWood® veneer to the PureBond® Plywood, a tongue and groove profile is cut into the flooring.

The boards are then sanded, finished, and surveyed for any blemishes. Our quality control team hand-checks each board and ensures that our flooring upholds our standards of hardness, durability, and beauty.

HempWood® Organic Flooring is offered in three options: Site-finished, Natural, and our Custom Color Collection. HempWood® Natural Flooring offers durability and strength all while maintaining an eco-friendly mission and no VOCs. Reach out to our sales team today at sales@hempwood.com or call (888) 338-1235 for a free quote!